Regular Slotted Container Company

Need Impressive RSC Box Style Designs and Manufacturing?

Our Box Manufacturing Company Abilities

We serve a broad range of industries, each with unique needs and custom requests.

Our Packaging Solutions

We serve a broad spectrum of industries and organizations requiring high quality custom packaging for their products and special-use cases. Explore how we can help you with your next packaging project.

Bags

We can design and manufacture high quality custom bags.

Boxes

We can design and manufacture high quality custom boxes.

POP Displays

We can design and manufacture high quality POP displays.

Shippers

We can design and manufacture high quality shippers.

Regular Slotted Container Design that Makes Your Brand and Products Stand Out

Once you contact us and define the sort of packaging you need, then we can provide you with a quote. Contact us today with any questions!

Some of the Industries We Serve

If You Want to Know Where to Buy Regular Slotted Carton Box Solutions, Contact Us Today

Packaging Services

We offer traditional and unique packaging and boxes that make your brand stand out.

Industry Packaging

We specialize in a creating customized packaging and boxes for a wide range of industries.

Creative Abilities

We can create prototypes, 3D rendering, proofs and have a broad variety of finishing services.

How to Choose a Quality RSC Container Manufacturer?

More Information

Complete Guide to Regular Slotted Containers (RSC): Types, Benefits, and Applications

Understanding Regular Slotted Containers (RSC)

What are Regular Slotted Containers?

Regular slotted containers, commonly known as RSC boxes, represent the most versatile and widely-used corrugated box style in the packaging industry. These shipping boxes feature a one-piece construction with flaps extending from both ends. The flaps meet in the middle when folded, creating a secure closure that makes RSCs ideal for various shipping applications.

The beauty of RSC design lies in its simplicity and effectiveness. Each box consists of precisely measured panels that fold together to create a robust structure. The equal-length flaps ensure consistent closure strength across all sides, while the single-piece construction eliminates weak points that might compromise package integrity during transit. This standardized design also facilitates efficient manufacturing processes, contributing to cost-effectiveness without sacrificing quality.

RSC Box Types and Materials

The construction of RSC boxes involves several material options, each serving specific packaging requirements:

- Single-Wall Corrugated: Ideal for standard retail packaging and lightweight items. This construction features three layers – outer liner, fluting, and inner liner – providing excellent strength-to-weight ratio for everyday shipping needs.

- Double-Wall Corrugated: Provides enhanced protection for heavier items. With five layers including two fluting layers, this construction offers superior stacking strength and impact resistance, making it perfect for industrial applications.

- Triple-Wall Corrugated: The ultimate in heavy-duty protection, featuring seven layers for maximum strength and durability. Ideal for extreme shipping conditions or very heavy items.

- Sustainable Materials: Including recycled content and eco-friendly alternatives. These options maintain structural integrity while reducing environmental impact through the use of post-consumer materials and biodegradable components.

The choice of fluting profiles also plays a crucial role in RSC performance:

- A-Flute: Provides excellent cushioning and stacking strength

- B-Flute: Offers better printing surfaces and good compression resistance

- C-Flute: Balances cushioning and crush resistance

- E-Flute: Perfect for smaller packages requiring high-quality printing

- F-Flute: Ultra-thin profile ideal for retail-ready packaging

Benefits of Using RSC Packaging

Modern businesses increasingly choose regular slotted containers for their numerous advantages:

- Cost-Effective Design: Minimizes material usage while maintaining structural integrity

- Versatile Applications: Suitable for e-commerce shipping and retail display

- Storage Efficiency: Ships flat and assembles quickly, optimizing warehouse space

- Product Protection: Provides reliable protection during transit and handling

Custom RSC Solutions for Your Business

Maximizing Efficiency and Durability with Custom RSCs

When it comes to custom shipping boxes, regular slotted containers offer unparalleled versatility. These lightweight containers provide robust protection while maintaining cost efficiency. By implementing custom dimensions and specifications, businesses can optimize their packaging process for maximum supply chain efficiency.

Advanced Protection Features

Modern RSC designs incorporate several protective elements:

- Reinforced corners for enhanced structural integrity

- Custom inserts for fragile item protection

- Moisture-resistant coatings for sensitive products

Industry-Specific RSC Applications

Heavy-Duty RSCs for Industrial Use

In the industrial sector, heavy-duty packaging solutions are essential. Our industrial-grade RSCs feature:

- Enhanced wall strength for maximum load capacity

- Specialized adhesives for secure closure

- Custom sizing for efficient palletization

Eco-Friendly RSC Solutions

Sustainable packaging has become increasingly important in today’s market. Our environmentally conscious options include:

- Sustainable Materials:

- 100% recyclable corrugated materials

- Post-consumer recycled content options

- Forest Stewardship Council (FSC) certified sources

- Biodegradable protective elements

- Environmental Impact Reduction:

- Minimal material waste designs

- Water-based inks and adhesives

- Energy-efficient production processes

- Optimized shipping dimensions for reduced carbon footprint

- Circular Economy Support:

- Easy-to-recycle single-material construction

- Clearly marked recycling instructions

- Take-back programs for commercial clients

- Waste reduction initiatives

Compliance and Customization

Meeting Industry Standards

Our comprehensive compliance program ensures all RSC boxes meet or exceed industry requirements:

- Testing Protocols:

- Edge crush testing (ECT) for stacking strength

- Burst strength verification

- Drop testing under various conditions

- Moisture resistance evaluation

- Quality Assurance:

- Regular material testing and certification

- Documented quality control procedures

- Batch tracking and traceability

- Third-party compliance verification

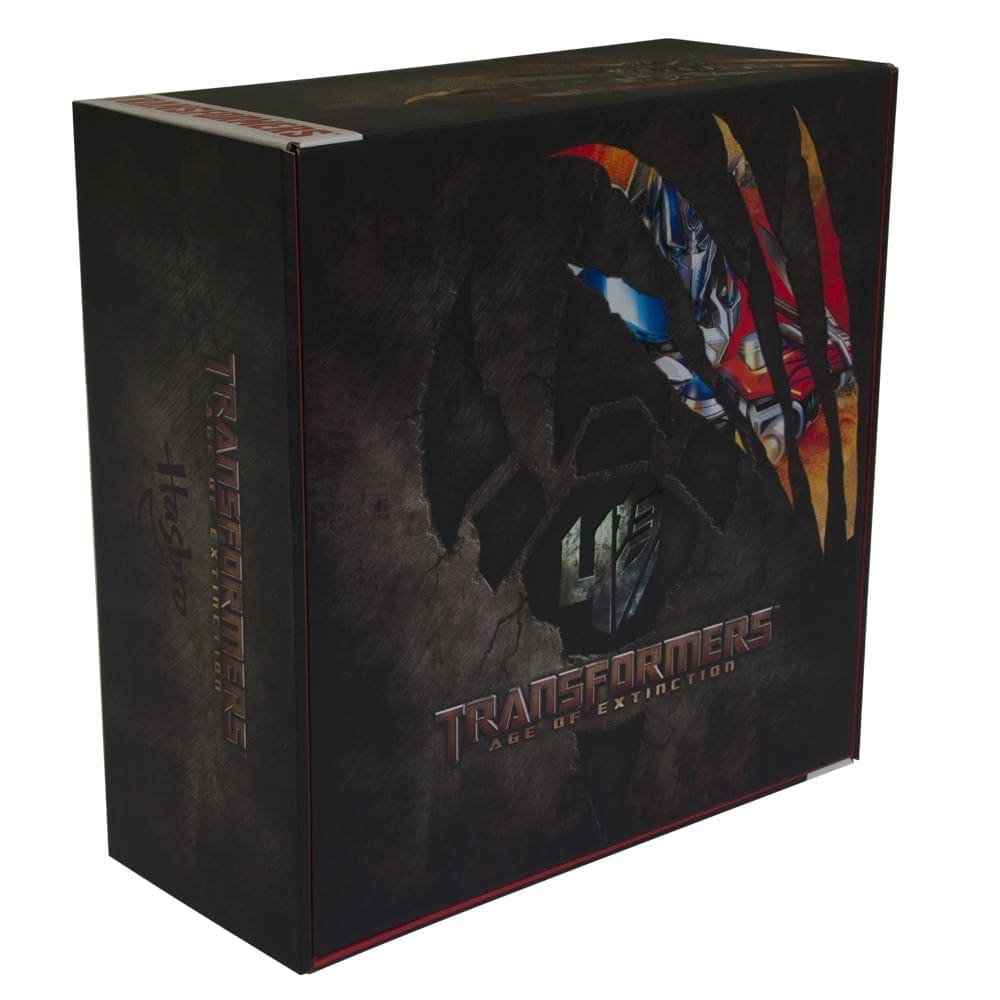

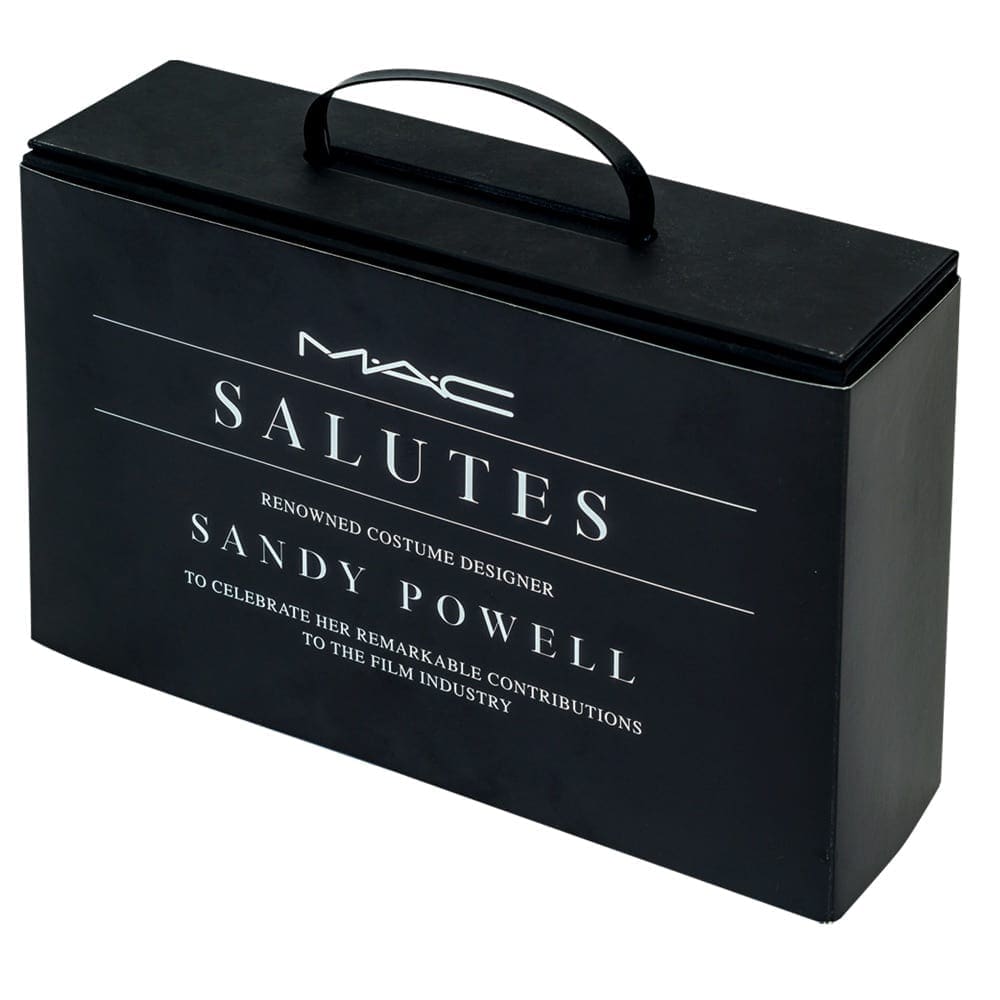

Advanced Customization Options

Enhance your brand presence with our premium printing capabilities and finishing options:

- Print Technologies:

- High-definition flexographic printing

- Digital printing for short runs

- Specialty ink applications

- Custom color matching systems

- Surface Treatments:

- Aqueous coatings

- UV protection layers

- Anti-scuff finishes

- Moisture barriers

- Structural Enhancements:

- Custom ventilation options

- Special closure systems

- Integrated handling features

- Display-ready configurations

Implementation and Support

Comprehensive Project Management

Our dedicated team provides end-to-end support for your packaging needs:

- Design Phase:

- Requirement analysis and consultation

- 3D modeling and prototyping

- Material selection guidance

- Cost optimization recommendations

- Production Support:

- Quality control documentation

- Production schedule coordination

- Inventory management solutions

- Just-in-time delivery options

- Ongoing Assistance:

- Technical support hotline

- Regular performance reviews

- Continuous improvement programs

- Staff training resources

Getting Started with VSL Packaging

Simple Ordering Process

Our streamlined process makes it easy to get started:

1. Initial Consultation

– Review your packaging requirements

– Discuss volume needs and timelines

– Explore customization options

– Address specific industry requirements

2. Design and Development

– Create detailed specifications

– Develop prototypes for testing

– Refine designs based on feedback

– Finalize production requirements

3. Production and Delivery

– Coordinate production schedule

– Implement quality control measures

– Arrange logistics and shipping

– Monitor delivery performance

Contact Us Today

Ready to enhance your packaging solution? Contact our team to discuss your RSC packaging needs and discover how we can help optimize your supply chain efficiency.

FAQs about Regular Slotted Containers

Q1: What makes RSCs different from other box styles?

A1: Regular slotted containers feature a unified design with equal-length flaps that meet in the middle, providing excellent strength and ease of assembly.

Q2: Are custom sizes available for RSCs?

A2: Yes, we offer fully customizable dimensions to meet your specific product requirements and shipping needs.

Q3: What industries commonly use RSCs?

A3: RSCs are widely used in e-commerce, retail, industrial manufacturing, and various other sectors requiring reliable shipping solutions.

Q4: How eco-friendly are your RSC options?

A4: We offer numerous sustainable options, including recycled content and biodegradable materials, to support environmental initiatives.

Q5: What is the minimum order quantity for custom RSCs?

A5: We offer flexible minimum order quantities to accommodate businesses of all sizes, ensuring accessibility to quality packaging solutions.